J. Davidson leading the way with LEFORT®

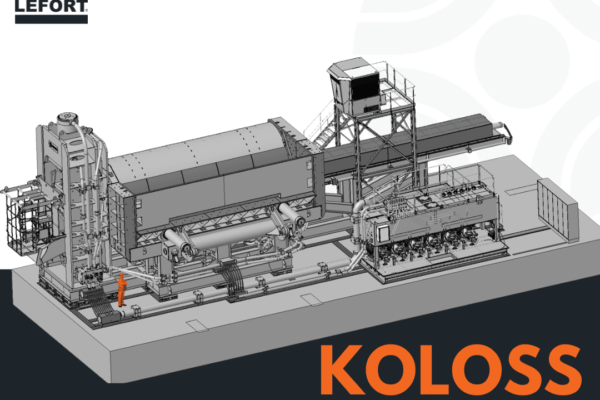

Recycling specialist J. Davidson has been operating a KOLOSS scrap shear with press wings since 2023. This heavy-duty machine has enabled this loyal LEFORT® customer to continue to grow and develop.

J. Davidson are one of the North West’s largest and longest established scrap metal dealers. Founded in 1970 by the late Jack Davidson, the business is now run by Jack’s son Jamie, with the help of his two sons Luke and Lee.

The company’s core business is the recycling of all types of metal products from end-of-life vehicles, industrial and construction demolition or commercial and domestic metal waste. Around 40,000 tonnes of metal are recycled every year.

With over 40 years’ experience in the scrap metal recycling sector, the company has become an expert in its field, but doesn’t want to sit on its laurels. Based on an ambitious 5 year replacement policy, the company remains at the cutting edge of technology by using the most up-todate equipment available in the scrap processing industry. That is the reason why they have chosen LEFORT® for their scrap shears for many years.

Dave Chapman, Managing Director at LEFORT® UK explains: “J. Davidson received their first LEFORT® machine, a 500 TSPFE (forerunner of the Conqueror) in 1997. This machine worked very well and enabled them to expand their business while continuing to work at a small site in Altrincham. The 500-ton machine soon proved too small, and they upgraded to a 600-ton machine. This soon became undersized, and they installed a Medium 700 as well as a Mobile 600 shear for outdoor projects. In 2012, they moved to their current site on Craven Road and took delivery of one of the first Midway 1000 TS shears manufactured by LEFORT®. The yard was a great success and, thanks to the enhanced performance of the 1000T shear, they were regularly able to process over 1000 tonnes of scrap per week. In 2023, they installed the LEFORT® KOLOSS 1300 TS. I believe that in total no less than 11 LEFORT® machines have passed through our customer’s hands. Apart from one used Mobile 600, all these machines were bought new.”

The new J. Davidson’s KOLOSS has a cutting force of 1,300 tons and a large 8-meter box. It is powered by a 2 x 600 HP diesel engine and has a cabin for easy operation. Additional features are the automatic centralized lubrication, and the hydraulic blade fixing system for rapid blade change. The hold-down with “combs” patented by LEFORT® reduces wear and the risk of scrap metal jamming. Jamy Davidson concludes: “We’ve been operating our KOLOSS for a year now. We’re still impressed by its performance. We regularly process 1,500 tonnes of scrap every week, and we’re confident in the reliability and profitability that the KOLOSS will bring us in the future.”

Vragen?

Contact met ons opnemen