LIDEX 2000 : Galloo wants full power for the port of Ghent

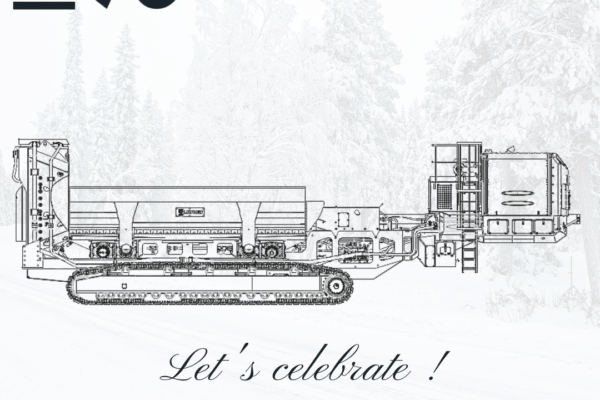

On Friday 22 March 2024, a festive atmosphere reigned at the Galloo site in Ghent. Staff were invited to the inauguration of the latest shear purchased by the Group, which is exceptional in more ways than one. It is both the largest shear owned by Galloo, and the largest made by the manufacturer in the LIDEX range of side compression machines.

Strategic site in Ghent

The Galloo Group has 45 sites in Belgium, France and the Netherlands. Some are small collection sites that operate without machines. Others are equipped with medium-sized scrap shears, generally 1,000 tonnes – the ‘mid size’ range in the Group’s jargon. Galloo Ghent is a particularly strategic site. Ghent is one of the largest port facilities on the North Sea, located at the southern end of the Ghent Terneuzen Canal. Ships enter the port via three locks, the largest of which measures 355 x 40 x 13.50 m. The canal and port are accessible to ships of up to 80,000 tonnes with a draught of 13.5 m. The site fulfils three major functions: firstly, it is the processing site for all the scrap metal located in the Ghent conurbation, the top 5 city in Belgium. Secondly, it is a hub for export activities. 1,000,000 tonnes of scrap metal pass through the site every year. Finally, the site is also active in ship breaking, i.e. of boats of course, but also of any other large floating object.

LIDEX2000 for maximum productivity

Group CEO Rik Debaere explains: “The company was using an old 2000-tonne American shear that was running out of steam. So, it was time to think about a more modern and much faster machine. However, we wanted to keep the same cutting force. The manufacturer followed our lead with a shear fitted with two 1000-tonne cylinders and a 10 x 2.60 m box identical to their 1700-tonne model. The machine has only been in operation for a few weeks, but we have already been able to appreciate its extreme speed – it goes around 3 times faster than its predecessor, which was admittedly very tired. With this machine, we will be able to process up to 5-6,000 tonnes of scrap per month. If we add scrap from other Galloo sites and external scrap suppliers, we load two 40,000-tonne ships a month in Ghent – you have to imagine ships 200 m long and 34 m wide loaded by two special cranes – that’s three full days of loading.”

The advantages of LIDEX

Galloo now has four LIDEX shears: one with a capacity of 1,000 tonnes, bought second-hand in 2013, two others with the same capacity, bought new and installed in 2021 and 2023, and finally the machine in Ghent. This is an opportunity for Rik Debaere to go back over the three key arguments that justify his preference for this model of machine, the only one to offer a fully automatic compression and shearing cycle. Firstly, the high efficiency of the hydraulics, which ensure smooth, reliable and jolt-free operation; secondly, the design and kinematics of the lid and preload table, which deposits the scrap metal in the middle of the compression box. Finally, Galloo is always impressed by the extremely fast, efficient and above all very safe blade changing system, as safety is also very important to the Group.

The adventure will not stop there, as Galloo has just confirmed the purchase of two more LIDEX1000 shears, to anticipate future needs to replace the 22 shears that the Group has and to expand through new site acquisitions.

Vragen?

Contact met ons opnemen