2024 Range : Unity is strength !

With the acquisition of the COPEX company in 2023, the LEFORT group, manufacturer of hydraulic shears and balers for the processing of scrap metal and metals, wants to better meet the expectations of recycling professionals, while writing a new page in its history.

Founded in 1947 and still 100% family-owned, LEFORT has become one of the world’s leading manufacturers of high-quality equipment for metal recycling.

The acquisition of the company COPEX by the LEFORT group will allow it to continue its development and strengthen its presence both locally and internationally. But also to be able to provide even more comprehensive services and solutions to its customers.

Firstly, its continued commercial strength and after-sales service: The integration of COPEX within the LEFORT Group has in fact enabled the two historic leaders to unite their respective networks to be more responsive and closer to customers in order to to respond even better to their specific needs.Then, by fundamentally overhauling the range of machines which now offer “the best of both worlds”.

Renowned specialist for its shear/baler/loggers, LEFORT is also the exclusive manufacturer of the TRAX, a self-propelled shear mounted on tracks. A unique internationally patented machine, the TRAX has unparalleled mobility on scrap yards or demolition sites

Continuing its innovation strategy, LEFORT now equips its machines with a cutting force of 700 tonnes or more with a new swan neck which perfectly meets the requirements of accessibility and safety for personnel responsible for operating and maintenance operations.

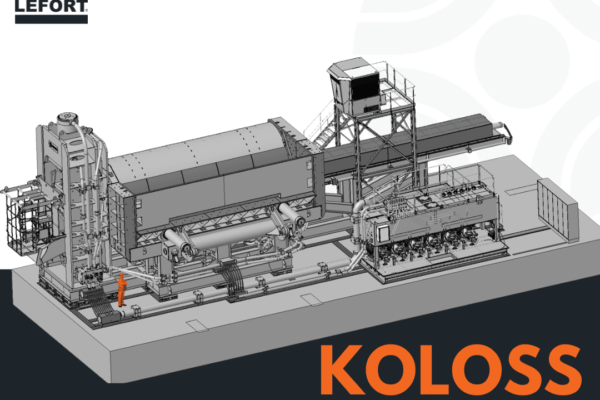

In 2024, the range of KOLOSS TS and BL heavy shea/balers becomes the KOLOSS and refocuses on the TS compression box. Already existing in 1000 and 1450 ton coupe force versions, the KOLOSS are now available in two new models of 1300 and 1700 tons available.

This range of heavy machines is completed by the LIDEX, a side compression shear/baler. A machine perfectly suited to the compaction and shearing of all types of scrap metal, and in particular heavy and bulky scrap metal, it is the only shear in its category which offers a fully automatic cycle, encompassing the compression and shearing stages. The LIDEX, already available in versions 1000, 1300, and 1700 tons of cutting force, has been expanded with two new versions in 1500 tons and 2000 tons for productions of up to 120 tons/hour depending on the model. The LIDEX will continue to be manufactured with the same attention to quality and robustness on the industrial site of the historic manufacturer COPEX in Caudan (56).

Finally, LEFORT now offers its new Webvisu remote maintenance system as standard. This device allows, from any digital medium – PC, tablet, mobile phone – to collect precise production data, monitor and intervene on the machine in real time, and thus optimize operation and maintenance.

Proof that, with a rich heritage, a solid reputation for quality and service and its passion for innovation, the “new” LEFORT Group is giving itself the means to successfully meet all the challenges of 75 years future.

Vragen?

Contact met ons opnemen