LEFORT turns 75 : The strength of experience

In 75 years, Lefort has become one of the most renowned manufacturers of balers, shears and shredders for the scrap metal recycling industry. Fully dedicated to these products, the company has rapidly evolved as an international group employing more than 200 people.

Today, Lefort exports 98% of its production and has a worldwide network of subsidiaries (in UK, France, Germany and USA) and official dealers covering five continents guaranteeing an efficient service without losing the family character that has always characterised Lefort. This impressive success is closely related to thecompany’s DNA: an independent family structure with an entrepreneurial force and an extraordinary passion for its customers and machines. Full control over the development of its products throughout the entire manufacturing process and services ensures the long lasting quality of its equipment.

The Lefort Group is now led by the third and fourth generations, Christian Lefort and two sons Antoine and Julien.

THE RECIPE FOR SUCCESS: QUALITY FIRST

Lefort’s reputation has been earned across decades thanks to the quality of its products and services. Since day one, each Lefort machine has been engineered for extreme conditions and built in its Belgian factories without compromise. From A to Z , Lefort masters what it does and the company is proud to be ISO 9001 certified. This certification testifies to the continuous optimisation , performance and quality approach which has marked out Lefort since its beginnings. For instance, 15 years ago it invested in a state-of-the-art factory exclusively for the manufacture of its own hydraulic cylinders. This massive commitment has paid off and allows the company to be totally independent and capable of repairing or rebuilding any of its cylinders within an unbeatable lead time.

CUSTOMER SERVICE

Customer service has always been the number one priority, starting with the quality of the machine, of course, but not ending there. Customer demand for rapid and tailored support has increased exponentially in recent years and this is exactly where Lefort makes the difference. The establishment of Lefort subsidiaries, supported by the factory and with their own technical and service teams, builds close relationships with customers by offering quick and professional service such as bladeschanges, on-site repair/retrofit works, maintenance, settings and so on. Thanks to recent multi-million investment, Lefort has the largest stock of spare parts which can be dispatched immediately all over the world.

LARGEST AND MOST VERSATILE

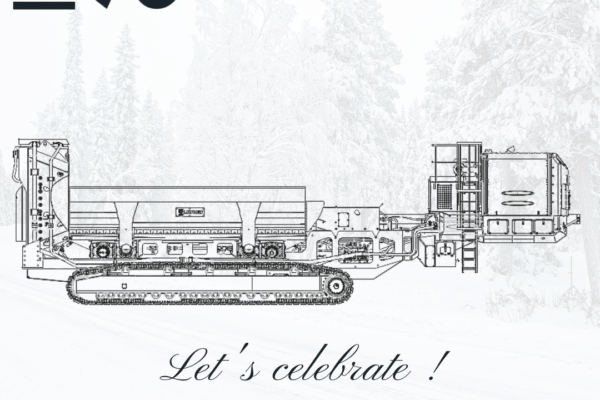

Selecting the right machine depends not only on the type, rate and volume of scrap metal being processed but also where the machine will work. Thanks to a very large range of machines, Lefort can accommodate any operation from the smallest to the largest scrap yard facilities. Ranging from 500 tonnes to more than 2 000 in stationary, mobile, portable or on tracks (patented) versions, Lefort can offer the right tool for the right job. A great example is the recently delivered Trax 1250. For this project, Lefort pushed all the technical boundaries by engineering a 1 250 of cutting force shear – on tracks.

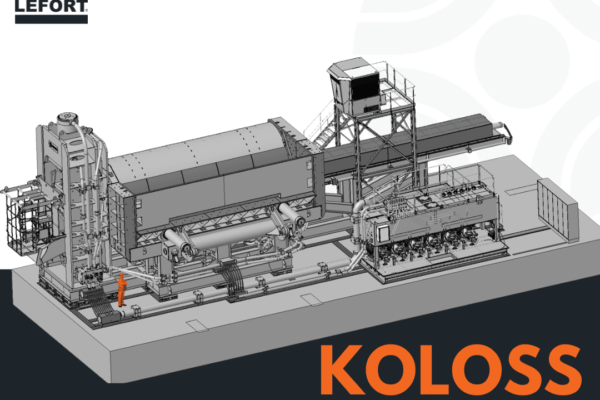

HEAVY DUTY KOLOSS

Modernised in 2021, the Koloss heavy-duty shears (weighing up to 550 tonnes) are extremely robust and productive machines capable of baling and shearing very large quantities of scrap metal. Lefort offers two different types of compression box: the side compression (BL) or the wrap-around (TS), available in 8m and 10m versions. Accompanied by Lefort product experts and engineers, each customer can configure their ideal machine according to the products to be processed at their desired production. The engine and the hydraulic system are configured to optimise performance while guaranteeing flexibility of use without over-stressing the machine.

Full article on : https://recyclinginternational.com/product-spotlight/lefort-turns-75-the-strength-of-experience/51078/

Domande ?

Contattaci