Lefort in line with Swedish recyclers

On 18 September, Lefort® received a delegation of 35 members of the Swedish Scrap Association. It was a great opportunity to discover the factory in Belgium, where all Lefort® machines are manufactured, see a machine demonstration and simply have a good time.

An old (but dynamic) lady almost a hundred years old…

The Swedish Association of Scrap Metal and Metal Traders (“Svenska Järn”) founded in 1930 has around sixty member companies, most of them in Sweden. Its historic aim is to serve the members financial and business interests, and to work for a healthy development of the trade and processing of RMR such as ferrous and non-ferrous scrap, and other recyclable materials.

… still dynamic and committed

According to Elinor Feuer, Director of the Chilanga recycling company, who has been chairing the Association for 3 years now, it is ‘extremely important for recycling professionals to get together to exchange ideas and learn from each other’s experience. It is a way of coming face to face with practices that are sometimes different and remaining mobilized. It also helps to develop solidarity between members’. That is the reason why, in addition to regular meetings, the Association organises an annual trip to discover new technologies, while enjoying a festive occasion. This was the framework for the visit to Lefort®.

Lefort® opens its doors

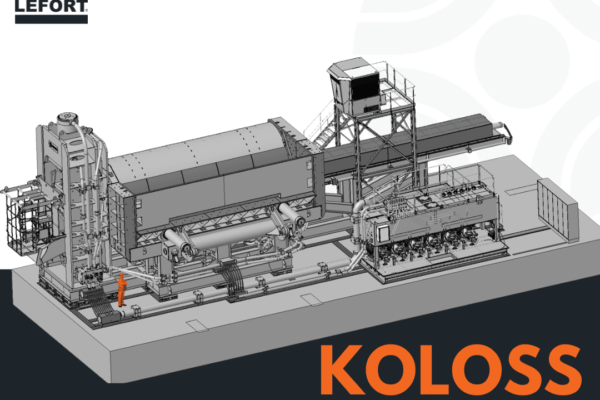

After a word of welcome and a brief presentation of the company and products, the guests were given a guided tour in small groups. They were generally impressed by the ‘company’s production capacity’, the ‘modernity of the factory’ and the ‘advanced industrial organisation’. Another point raised by visitors: Lefort® hydraulic cylinders are manufactured in-house (400-600 units per year), thus enabling the supplier to respond quickly to urgent replacement needs. The automated warehouse was also a big hit with the audience, in which 25,000 item references are hold, representing the largest stock of parts in the sector.

From most points of view, it is important to see the machines, but it is also important to find out where and how they are made, and the strategy and philosophy behind them.

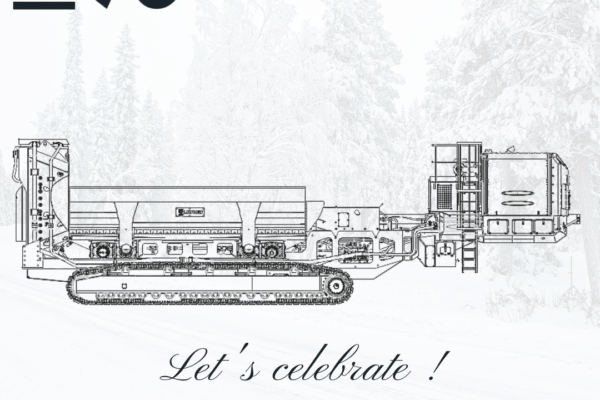

After a demonstration of the internationally patented Trax scrap shear, everyone gathered for a convivial lunch. Before continuing their journey to Germany, visitors were each presented with a box of chocolates, the other speciality of Belgium….

Domande ?

Contattaci