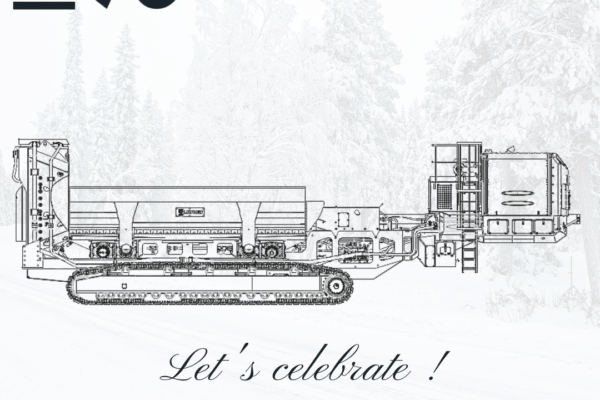

New TRAX shear At Bader Recycling : An all-terrain machine

Swiss company Bader Recycling has been operating a TRAX 700 at its Martigny site since February 2024. According to the company, which does a lot of demolition work, this track-mounted machine can go to any site.

An expert and committed company

For Bader Recycling, active in Frenchspeaking Switzerland, the story began in 1850, when the great-grandfather of the Bader family started his recycling business. 170 years later, we are in the 4th generation, with Gérald Bader and his sister running the company founded in 1974 by their parents. Specialising in the recycling of scrap and metal, Bader Recycling is an expert in the dismantling of very large metal structures, including special, difficult jobs such as removing bulky 150-tonne boilers or working on sites that are difficult to access. The company also attaches great importance to passing on its skills and knowhow and is heavily involved in apprentice training. In fact, it is listed as a referee for apprenticeships in Switzerland.

The TRAX: Extreme mobility and reduced costs

While the rest of the Bader Group, including Bader Recycling, only had static shears/balers/loggers, the Director of Bader Recycling saw the advantages of having mobile equipment. “We have some very large sites where it’s more efficient to bring equipment to the site than to have to bring the scrap back to our site in Martigny. The big advantage of the TRAX, compared even to mobile shears on wheels, is that you can go anywhere. Sometimes the places we go are like battlefields. Yet the TRAX, with its powerful tracks, always manages to find its way around”, says Bader. Increasingly expensive energy means that recycling companies need to minimize travel and transport. Wit the TRAX Bader Recycling made deep cuts in their costs.

Ease of transport and efficiency of the LEFORT® system

Bader opted for the TRAX 700 because it was the largest model in the range that could be moved without having to remove the tracks. “When we need to move the machine, we just load it up, and once it’s on the site, it’s immediately operational. It’s super easy!” Bader also emphasises the machine’s extreme speed: “I’m impressed by the speed of the movements and the hydraulics. I think LEFORT® is way ahead of other manufacturers.” The Web Visu remote maintenance option on the machine is particularly appreciated by the operator. “At the beginning, we found that the lubrication was a bit strong on our shear. LEFORT® was able to optimize lubricatioin a remote way and this was changed injust a few minutes.”

2024: Realistic optimism

Despite all the uncertainties in the world, Bader thinks that business will remain buoyant in 2024. “Recycling will continue to grow as resources become scarcer. The recycling chain is an essential element that will have to work better and better in the years to come. What’s more, companies have understood importance of recycling and are sorting their materials better and better.” Against a backdrop of rising energy costs and the development of solar panels, the Swiss recycler believes that hybrid solutions for machines like TRAXs should make more and more sense. It’s a good thing that LEFORT® has just launched the electric E-TRAX model, equipped with a diesel-only module for moving the machine, with the firm ambition to stay “one step ahead”.

Domande ?

Contattaci