New LEFORT TRAX 700T @William Waugh

LEFORT® recently delivered a 700-ton TRAX shear to the Scottish company William Waugh, dedicated to the recycling of ELVs and ferrous and non-ferrous metals. This new acquisition marks a significant milestone in the company’s history, which is steeped in a rich family tradition of recycling.

A family history that spans centuries

The company is deeply rooted in the history of recycling, a sector in which the Waugh family has been involved for over 150 years. The earliest traces of metal recycling activities date back to the 19th century, a legacy that William Waugh continues to proudly uphold today. It is a family-run model, passed down through generations, that has allowed the company to thrive while maintaining its core values.

A site in continuous evolution

The Granton site, a historic industrial area in Edinburgh, has been the heart of William Waugh’s operations for over 50 years. Today, the site continues to evolve, with ongoing investments in modern infrastructure and machinery, enabling the company to maintain its leadership in an ever-changing industry. The arrival of the 700-ton TRAX in September confirms the company’s commitment to staying at the forefront of technical progress.

Strategic choice for more efficient recycling

The decision to acquire a 700-ton TRAX shear was driven by the need to modernize equipment and meet growing production demands. Alan Waugh, one of the company’s leaders, expressed his admiration for the flexibility of the TRAX, movable anywhere on the scrap yard thanks to its tracks.

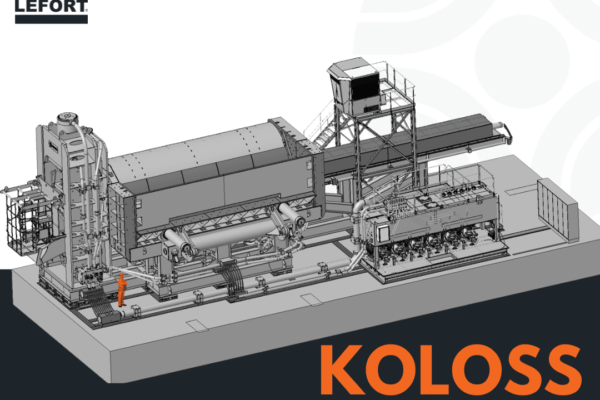

The TRAX 700 at William Waugh is a state-of-the-art machine with impressive technical features. With a cutting force of 700 tons, it is capable of processing large volumes of ferrous and non-ferrous metals. Each 325-ton press lid, along with a 180-ton pusher, ensures optimal material compression. The hold-down has a force of 120 tons, while the box measures 6.6 meters in length, allowing for the handling of larger volumes of material.

This shear is equipped with a 400 HP diesel engine and weighs nearly 80 tons, ensuring robustness and durability. It allows William Waugh to process up to 20 tons of metal per hour and produce over 30 bales per hour.

The acquisition of this new TRAX machine marks a turning point for the company, which combines its family tradition with technological innovations to meet the future challenges of metal recycling.

Preguntas ?

Contacto con nosotros